How to Connect Two LED Strips Without Connectors: DIY Guide

How can you connect two LED strips without using connectors? Our DIY guide provides simple steps for seamlessly joining LED strips for continuous illumination. From preparing the strips to soldering the connection, we’ll walk you through the process with ease. Say goodbye to bulky connectors and hello to a sleek, uninterrupted lighting setup with our expert tips!

Key Takeaways

- Identify connection points on LED strips for soldering.

- Carefully strip insulation off wires and LED strip.

- Solder wires to copper pads on each LED strip.

- Consider conductive glue as an alternative to soldering.

- Test the connection after glue dries for security.

Understanding the Basics of LED Strip Lights

LED strip lights are available in various types, each providing unique features suitable for different applications. While LED strip connectors offer a seamless and efficient solution for connecting these strips, there are scenarios where direct connections are necessary. This method involves more challenges, such as potential damage to the strips or unreliable connections. However, with proper care and attention to detail, direct connections can be a viable solution, opening new possibilities for innovative lighting designs and installations.

Preparing for the LED Strip Connection Process

Before starting the connection process, gather all necessary tools and ensure safety measures are in place. Select the appropriate type of LED strip for your project, considering factors like brightness and flexibility. Working in a well-ventilated area and wearing safety goggles are crucial for safety. Although connectors are convenient for joining LED strips, soldering provides a more seamless look and reliable connection.

Step-by-Step Guide to Connecting LED Strips Without Connectors

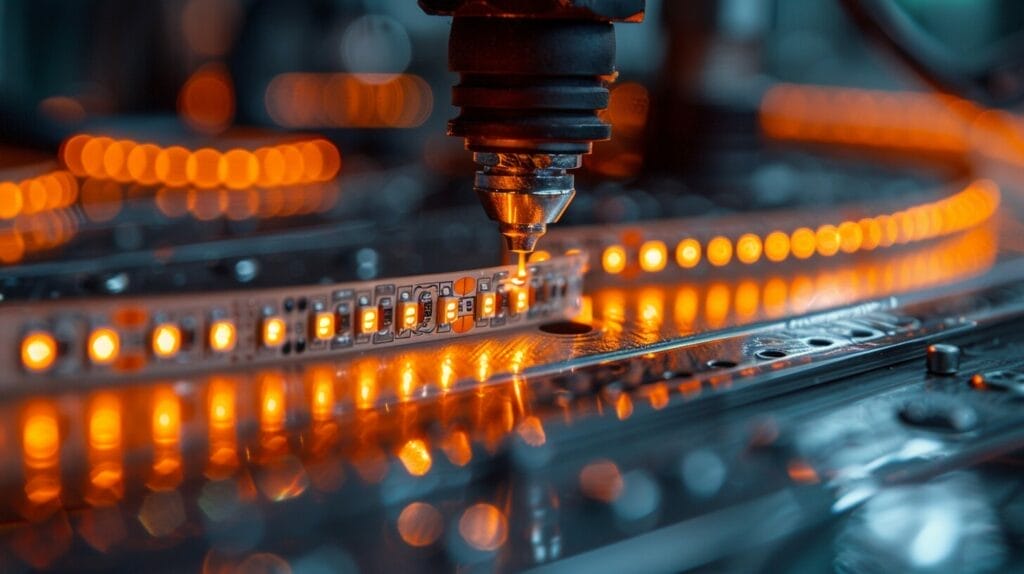

Let’s immerse ourselves in the step-by-step process of connecting LED strips without the need for connectors. Begin by identifying the connection points on the LED strips where you want to join them.

Next, strip the insulation off the wires and LED strip to expose a small section of the copper pads. Then, using a soldering iron, carefully solder the wires to the copper pads on each LED strip. Make sure the solder creates a secure and conductive bond between the wire and the pad.

If soldering isn’t your preferred method, an alternative is to use conductive glue. Apply a small amount of the glue to the connection points on both LED strips, press them together, and allow the glue to dry. This can provide a quick and easy way to connect the LED strips without the need for soldering. Remember to test the connection once the glue is dry to confirm it’s secure.

Testing and Troubleshooting the Connected LED Strips

After successfully connecting the LED strips without connectors, the next critical step is testing and troubleshooting to guarantee peak functionality. Testing is essential to make certain that the connection is secure and the LED strips are functioning correctly.

To test the strips, simply power them on and observe if all the LEDs light up uniformly without flickering. If any issues arise, troubleshooting becomes necessary. Common problems include poor connections, incorrect wiring, or damaged LED components. To troubleshoot, check the wiring, connectors, and power source for any faults.

Maintaining a stable connection is important for the longevity of the LED strips. To achieve this, make sure the connection points are secure and insulated properly. Additionally, if you plan to use the LED strips outdoors or in damp areas, ensuring they’re waterproof is essential to prevent damage.

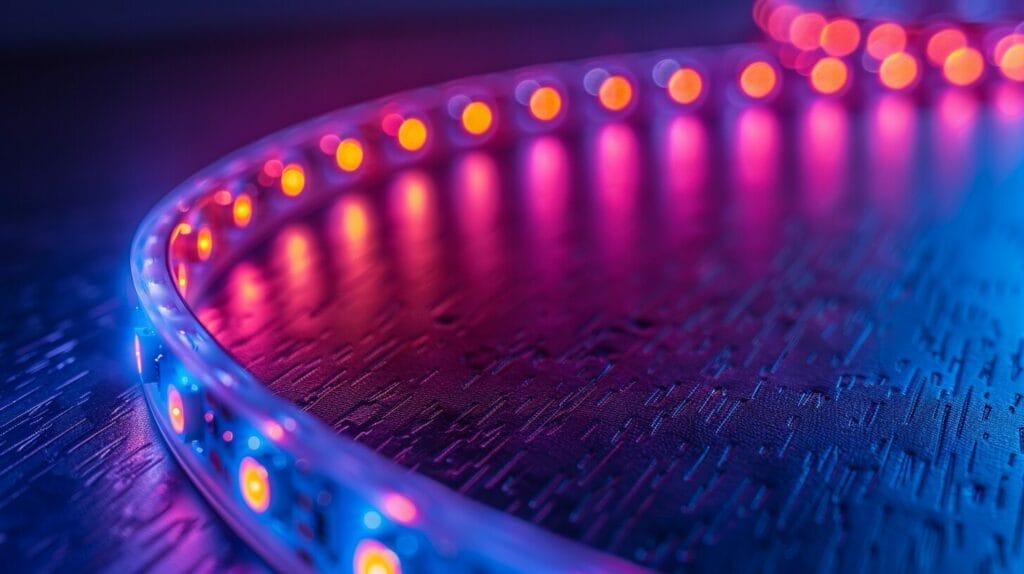

Enhancing LED Lighting with Flexible and RGB Options

To further enhance your LED lighting, consider using flexible and RGB LED strips for customizable and dynamic lighting solutions. Silicone-coated LED strips are ideal for outdoor use, providing protection against moisture and dust. Experiment with different color combinations and control options to elevate your lighting design.

Conclusion

Overall, connecting two LED strips without connectors is a straightforward process that can be easily done with a few basic tools and some patience.

By following the step-by-step guide outlined in this DIY article, you can successfully join your LED strips together and create a seamless lighting display.

Remember to test and troubleshoot your connections to make sure everything is working properly, and consider exploring flexible and RGB options to enhance your LED lighting experience even further.

Happy DIY-ing!

Frequently Asked Questions

Can I connect two LED strips without connectors?

Yes, you can connect two LED strips without connectors by using wires and soldering.

What is the best way to connect LED strips without connectors?

The recommended method is to strip the wires at the end of each strip, solder them together, and insulate the connection with silicone for waterproofing.

Do I need to solder the wires when connecting LED strips?

It is recommended to solder the wires when connecting LED strips for a secure and permanent connection.

What are the advantages of soldered connections for LED strips?

Soldered connections provide a reliable and sturdy connection that ensures the LEDs illuminate properly without any voltage drop.

How do I ensure the LED strips are connected properly when soldering?

To ensure the LED strips are connected correctly when soldering, make sure to match the positive and negative terminals of each strip.

Can I connect different types of LED strips together?

Yes, you can connect different types of LED strips together as long as they are compatible in terms of voltage and technical specifications.