How Do IGBTs Work: Enlightening IGBT Circuit Applications

While eagerly anticipating the day when we can plug our brains directly into the internet, let’s take a moment to appreciate the unsung heroes of our digital era: Insulated Gate Bipolar Transistors (IGBTs). These remarkable little devices, like an equivalent circuit of BJT and MOSFET, are at the heart of many modern technologies, from electric cars to renewable energy systems. Yet, their inner workings remain a mystery to many.

Our mission is to unravel this mystery. We’ll begin with an overview of IGBTs’ structure and characteristics, then dive into the principles behind their operation in circuit applications. We’ll also explore the various types and variations of IGBTs and their practical applications across different industries.

So, how do IGBTs work? Let’s embark on this electrifying journey together, where we will explore the power transistor, the IGBT, in depth.

Key Takeaways

- IGBTs are versatile semiconductor devices used in high voltage and high current applications.

- They combine the advantages of BJTs and MOSFETs, offering lower conduction losses and higher voltage blocking capability.

- IGBTs have three operational modes: cutoff, active, and saturation. In the active mode, minority carriers play a key role, crucial for circuit design and the PN junction improvement.

- Different types of IGBTs are available to deliver optimal performance for various applications in industries such as power electronics, motor drives, renewable energy systems, and transportation systems.

Introduction to IGBTs: An Overview of Insulated Gate Bipolar Transistors

IGBTs are versatile semiconductor devices that have a unique advantage over alternatives like MOSFETs in various electronic circuits. IGBTs combine the best features of two types of transistors: bipolar junction transistors (BJTs), npn transistors, and metal-oxide-semiconductor field-effect transistors (MOSFETs).

These devices, which are essentially electrons movers between collector and emitter, are primarily used in high voltage and high current applications, where they shine due to their high input impedance and fast switching capabilities. They, whether n-channel or p-channel IGBT, are versatile and can have a drive circuit that allows for current to flow, given a positive gate voltage. They have a wide range of applications, including motor drives, power supplies, and renewable energy systems where the IGBT provides key functionality.

Despite their advantages, IGBTs do have drawbacks, such as the necessity to maintain a certain gate-emitter voltage, usually a negative voltage, above the threshold. The complexity of their structure can make their design and manufacturing processes more challenging.

Understanding the Structure and Characteristics of IGBTs

So, what’s it about the structure of two types of IGBTs – punch through IGBT and asymmetrical IGBT that make them so versatile and effective in catering to the necessity of a negative voltage?

The answer lies in the construction of IGBT. Essentially, an IGBT device is a combination of two power electronic devices, the Bipolar Junction Transistor (BJT) and the Metal Oxide Semiconductor Field Effect Transistor (MOSFET). This unique structure of IGBT allows for the high input impedance of a MOSFET and the low on-state power loss of a BJT.

Now, let’s delve into the characteristics of IGBT that give it an edge over other power electronic devices, like its effective handling of input current.

- Voltage Rating: IGBTs, whether NPN or PNP, can handle high voltage levels, typically from 600V to 1.2kV, making them suitable for various high-power applications.

- Current Handling: The IGBT structure is designed to handle high current levels, making it a reliable choice for power supply systems.

- Switching Speed: IGBTs exhibit fast switching speeds and minimal tail current, ensuring efficient operation in applications like inverters and converters.

- Conduction Losses: Due to the construction of IGBT, it has lower conduction losses, contributing to energy-efficient applications.

The unique IGBT structure, coupled with its superior characteristics, makes it a game-changer in the world of power electronics. With their ability to function in reverse bias and their skilled handling of charge carriers, it’s clear why IGBTs are seeing a rise in application across diverse fields, from electric vehicles to renewable energy systems.

The Working Principles of IGBTs in Circuit Operations

To fully understand the effectiveness of IGBTs in circuit operations, we need to discuss their three operational modes: cutoff, active, and saturation. Each mode plays a crucial role in the working principles of IGBTs, making these power switches reliable and efficient.

Here’s a summary of these modes:

- Cutoff: IGBT is off, no current

- Active: IGBT is on, current flows

- Saturation: IGBT is fully on, maximum current

The process of turning an IGBT on and off is an integral part of its operation. The voltage and current waveforms during these switching transitions provide valuable insights into the device’s performance. By understanding these working principles, including the gate-emitter voltage, we can design and improve IGBT circuit applications, creating more efficient, reliable, and sustainable electronic solutions for the future.

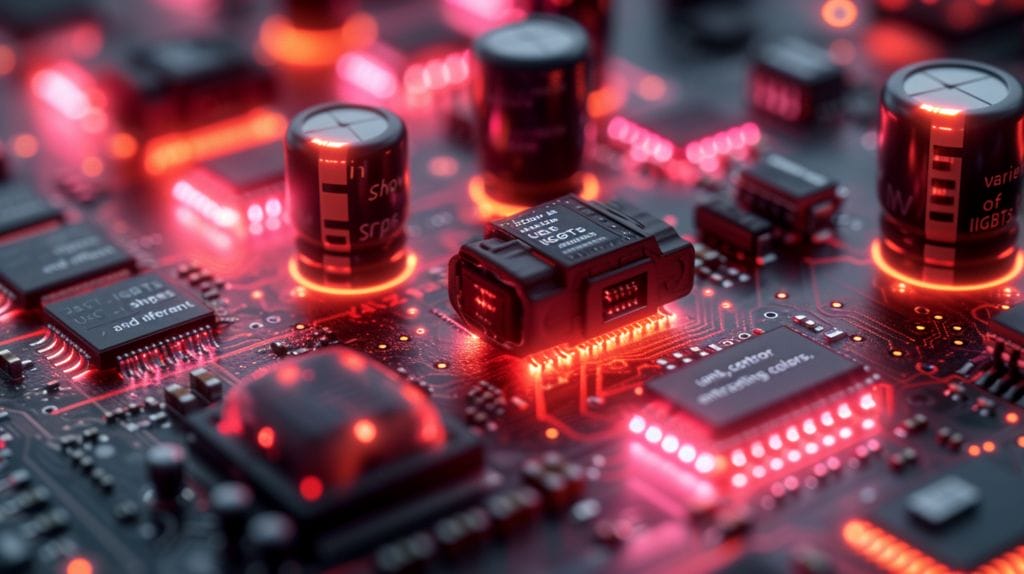

Types and Variations of IGBTs for Different Applications

There are various types and variations of IGBTs designed for different applications. The types of IGBTs available in the market range widely, including n-channel and p-channel IGBTs, thanks to the unique structure of the IGBT, which caters to diverse applications like industrial motor control and renewable energy systems.

- Standard IGBTs: Balance between conduction and switching losses, ideal for high-power applications.

- Trench Gate IGBTs: Lower conduction loss and better efficiency, suited for power supplies and inverters.

- Low-Power IGBTs: Providing high efficiency and excellent thermal performance, these power transistors are designed for lower power applications.

- High-Power IGBTs: Superior power handling and enhanced durability, threshold voltage playing a key role, designed for high-power applications like electric vehicles and industrial motors.

Practical Applications of IGBTs in Various Industries

In numerous industries, IGBTs serve as a crucial part, particularly in applications like power electronics, motor drives, renewable energy systems, and transportation systems, by controlling the forward voltage. From frequency converters and power supplies to solar inverters and wind turbines, IGBTs provide efficient, reliable power control.

How Do IGBTs Play a Role in Electrical Wiring and Circuit Applications?

IGBTs play a crucial role in electrical wiring and circuit applications, particularly in controlling power flow and voltage levels. By integrating IGBTs into these systems, superior performance and efficiency can be achieved, providing valuable ground and neutral wiring insights for engineers and designers.

What Are the Application of IGBTs in High Power LED Circuits?

IGBTs are essential in high power LED circuits as they can handle the max voltage for LED without overheating. This allows for efficient power conversion and control in LED applications. By using IGBTs, LED circuits can achieve better performance and reliability, making them ideal for high power settings.

Future Trends and Advancements in IGBT Technology

IGBT technology, particularly the concept of collector to emitter, is a field ripe with innovation. As we look towards the future, we can see several emerging trends set to revolutionize IGBT circuit applications:

- Emerging Technologies and Materials: New materials like silicon carbide and gallium nitride are set to improve not only IGBT performance but also BJT and MOSFET technology.

- Next-Generation IGBTs: Future IGBTs will have higher power capacity, improved switching speeds, and better thermal management.

- Challenges and Opportunities: Balancing performance enhancement while maintaining affordable costs will be the key challenge.

- Impact on Industries and Applications: As IGBT technology evolves, it will open new doors for various applications, including renewable energy, electric vehicles, and power electronics.

Conclusion

We’ve probed deep into the realm of IGBTs, understanding their structure, their functioning, the various forms they come in, and the concept of a threshold voltage, especially the role of the n-channel MOSFET.

We’ve seen their practical applications across industries and the future trends shaping this technology. It’s clear IGBTs play a pivotal role in power electronics, transforming how we use and regulate power.

As we continue to innovate and adopt the use of reverse voltage, the possibilities for IGBTs, as well as BJT and MOSFET, are endless with the ongoing improvements in drive circuit technology.

Here’s to the bright future of IGBT technology!

Frequently Asked Questions

What is the structure of an IGBT?

An IGBT (Insulated Gate Bipolar Transistor) functions such that charge carriers, especially minority carriers, play an essential role across a silicon dioxide layer. IGBT has three main layers: the N-type drift region sandwiched between the P-type base and N+ buffer layers, also known as the N- layer.

How does an IGBT work?

An IGBT operates as a three-terminal power semiconductor device, much like a BJT and MOSFET, but with an emphasis on current flows through the device. IGBT combines the characteristics of a MOSFET, a bipolar junction transistor (BJT), and an npn transistor to control the flow of current.

What are the characteristics of an IGBT?

IGBTs, particularly punch through IGBT, have the ability to handle high voltage and high current, making them suitable for various power electronic applications.

What are the types of IGBT?

Based on their voltage and current-carrying capabilities, IGBTs are categorized into symmetrical and asymmetrical types, especially those that use a positive gate voltage in their applications.

What is the function of the gate terminal in an IGBT?

The gate terminal in an IGBT controls the switching action by applying a gate voltage to modulate the flow of carriers in the device’s drift region.