How to Solder LED Light Strips: A Guide to Soldering LED Strips Easily

LED light strips can brighten up any space. But what if you need to cut or join them? Many people think soldering LED strips is hard. It’s not! You can do it at home with the right tools and steps.

This guide will show you how to solder LED light strips easily.

I’ve worked on many home projects over the years. Soldering LED strips is one of my favorite tasks. It’s simple once you know how. In this post, I’ll share my tips for clean, strong solder joints.

Ready to light up your home? Let’s get started!

Key Takeaways

- You need a soldering iron, solder, wire cutters, and safety gear to solder LED strips.

- Strip and tin wires before soldering. Clean and tin LED strip pads too.

- Solder at 500-600°F. Hold wires still until solder cools for strong bonds.

- Use heat shrink tubing to protect soldered joints from shorts.

- Test LED strips after soldering. Fix any dark spots by re-soldering bad connections.

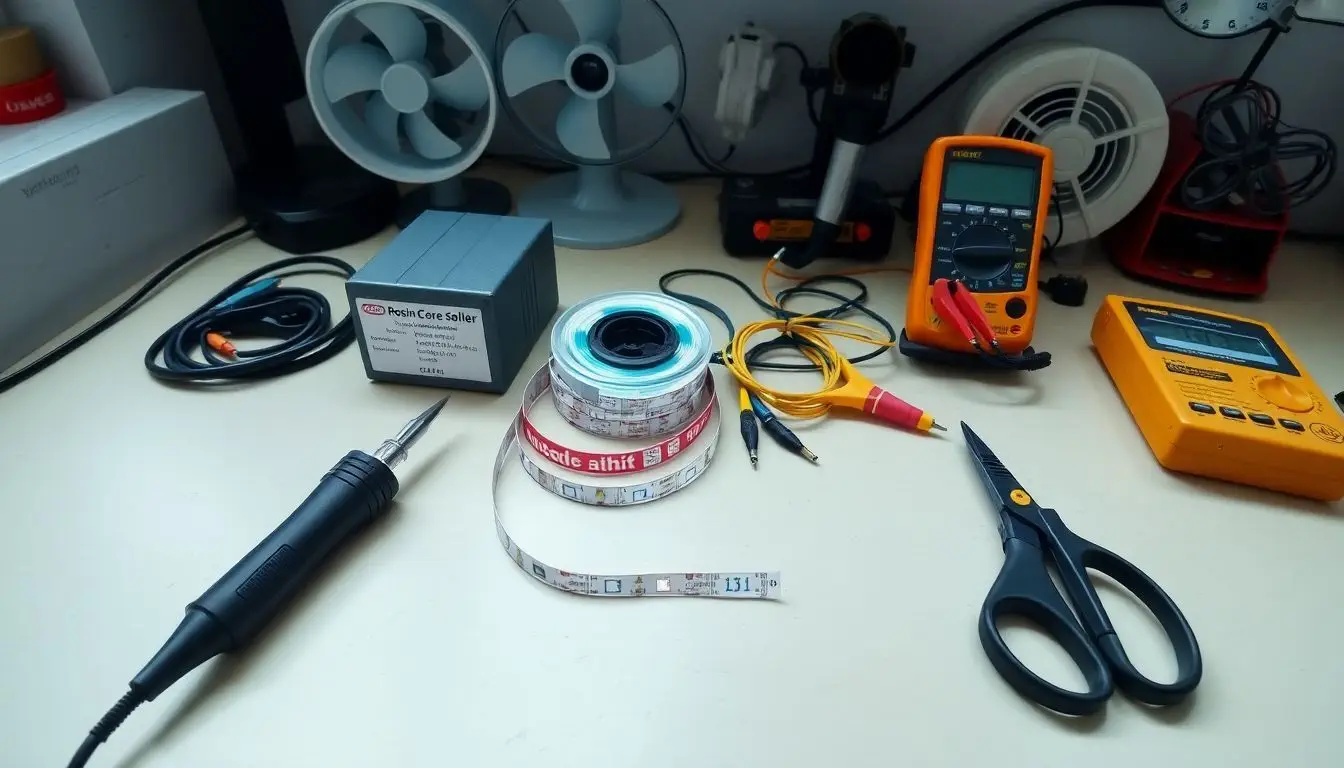

Necessary Tools and Materials for Soldering LED Strips

You need specific tools to solder LED strips well. Here’s what you’ll need:

- Soldering iron (30W-60W, adjustable temperature)

- Thin rosin core solder

- Wet sponge or steel pad

- Wire cutters

- Knife

- Scissors

- Stranded wire (18-22 AWG for RGB)

- LED strip

- Heat shrink tubing

- Helping hands or clamps

- Safety glasses

- Ventilation fan

- Flux pen (optional)

- Multimeter (for testing)

Preparing LED Strips for Soldering

Get Your LED Strips Ready

Prepping your LED strips is key. You’ll need to strip wires and tin solder pads before you start.

Stripping and Tinning the Wires

Proper wire prep is key for strong LED strip connections. You’ll need to strip and tin your wires before soldering.

- Strip about 1/4 inch of insulation from the wire ends using wire strippers. Be careful not to nick the copper strands.

- Heat your soldering iron to 315-370°C (600-700°F). This temp range works best for tinning.

- Touch the hot iron tip to one side of the exposed wire. Apply a small amount of solder to the other side.

- The solder should melt and flow evenly, coating all the wire strands. This creates a solid tinned end.

- Repeat for all wire ends you plan to solder. Clean your iron tip often for best results.

- Use 18-22 AWG stranded RGB wire for LED strips. This gauge range offers the right mix of flexibility and current capacity.

- Practice tinning on scrap wire pieces first. It takes a light touch to avoid using too much solder.

- Let each tinned wire end cool fully before handling. The solder stays liquid for a few seconds after removing heat.

- Inspect your work – properly tinned wires look shiny and smooth with no loose strands poking out.

Tinning the LED Strip Solder Pads

After prepping your wires, it’s time to focus on the LED strip itself. Tinning the solder pads on your LED strip is a crucial step for a strong connection.

- Clean the copper pads on your RGB LED strip with rubbing alcohol.

- Heat up your soldering iron to the right temp for your solder type.

- Apply a tiny drop of solder to each pad on the strip.

- Move quickly to avoid overheating the LEDs.

- Make sure the solder looks shiny and silver when it cools.

- Don’t use too much solder or it could mess up the colors.

- Check that the solder sticks well to the pad.

- Let the pads cool fully before touching them.

- Repeat for all the pads you plan to connect wires to.

- Double-check your work to ensure even coverage.

Step-by-Step Soldering Process

Now, let’s get your hands dirty! This part will show you how to join wires to LED strips step by step. You’ll learn to use a soldering iron and apply heat shrink tubing for safety.

Soldering Wires to LED Strip Pads

Soldering wires to LED strip pads is a key step in creating custom lighting. Follow these steps to connect your wires safely and securely.

- Heat your soldering iron to 500°F-600°F. This temp works best for most LED strips.

- Secure the LED tape with a weight. This keeps it steady while you work.

- Apply solder to the copper pads on the LED strip. Heat the pad first, then add solder.

- Strip 2-3mm of insulation from your wire. This exposes the metal strands inside.

- Tin the exposed wire ends. Melt solder onto the bare metal to prep it.

- Reheat the solder on the LED pads. Press the tinned wire into the melted solder.

- Hold the wire still until the solder cools. This makes a strong bond.

- Check for a “cold solder joint“. If the solder looks dull, reheat it for a better connection.

- Use heat shrink tubing over the joint. This protects your work from shorts.

- Test your connection with a multimeter. Make sure power flows correctly.

Applying Heat Shrink for Insulation

Heat shrink tubing keeps your LED strip connections safe and secure. It’s a key step in the soldering process. Here’s how to apply heat shrink:

- Slide a piece of heat shrink tubing over the soldered joint.

- Use a heat gun to shrink the tubing around the connection.

- Make sure the tubing covers the entire soldered area.

- Apply heat evenly to avoid burning or damaging the tubing.

- The tubing will tighten and form a snug seal as it shrinks.

- This insulation prevents sparks and protects against short circuits.

- If you don’t have heat shrink, electrical tape can work in a pinch.

- Heat shrink offers better protection than tape for long-term use.

- Choose tubing that’s slightly larger than your wire for easy sliding.

- Shrink the tubing until it’s tight but not so hot it melts the wire insulation.

Now that your connections are insulated, it’s time to test your newly soldered LED strips.

Testing and Troubleshooting Your Soldered LED Strips

Test your LED strips after soldering. Plug them in and check if all lights work. Use a multimeter to test for good connections. Look for cold solder joints – they can cause failures.

Make sure you’ve used the right voltage and polarity. If some LEDs don’t light up, you may need to re-solder those spots.

Fix problems by reconnecting or re-soldering bad sections. Dark LEDs often mean faulty joints or connections. Check each solder point carefully. Clean and re-tin any iffy spots. Then solder again with the right heat.

Test after each fix to ensure it worked.

Conclusion

You can do this! Soldering LED strips is an enjoyable skill to develop. As you practice, you’ll create impressive light displays. Work safely and take your time. Your newly soldered LED strips will enhance any space.

Now go illuminate your surroundings!

For more advanced techniques on customizing your LED light setup, check out our guide on how to mix colors with an LED lights remote.

FAQs

1. What tools do I need to solder LED strip lights?

You’ll need a solder iron, solder, wire, and heat-shrink tubing. Don’t forget flux – it helps the solder flow. A clean tip on your iron is key.

2. How do I prep the LED strip for soldering?

First, tin the pads on the strip. This means adding a bit of solder. It should look silver and shiny. Don’t use too much heat – you might damage the strip.

3. What’s the best way to connect wires to the LED strip?

Pre-tin the wires, then place them on the pads. Touch the iron to both – just enough to melt the solder. A small blob is all you need. Let it cool before you move it.

4. Can I solder RGBW LED strips the same way?

Yes, but be careful. RGBW strips have more wires. Match colors right. Take your time. If you rush, you might cross wires and mess up the colors.

5. What power supply should I use for my LED strip?

It depends on your strip. Most use 12VDC or 5VDC. Check the label. For long strips, you might need more juice. A good power supply is key for a bright, steady light.

6. Is soldering better than using connectors for LED strips?

Soldering is stronger and more reliable. Connectors are easier but can come loose. For a long-term setup, soldering is best. Just be patient and practice first.

References

- https://www.instyleled.co.uk/blog/how-to-solder-led-tape/

- https://www.ecolocityled.com/category/led_tutorials_rgb_solder?srsltid=AfmBOopHmMViWV8LUwiOKuXvTH7GoMabXx3Ma9clpZvzSVo4L2pEVCoh

- https://help.wired4signsusa.com/en-US/soldering-led-strips-a-step-by-step-guide-398568

- https://www.instructables.com/Soldering-RGBW-and-RGB-LED-Strip-Tape/

- https://www.ecolocityled.com/category/led_tutorials_rgb_solder?srsltid=AfmBOor04QjThC5Pe4WcayzfH-m4ZEx1zulhH_kt0T60Wdg2tE_LlM6P

- https://sirs-e.com/general/solder-led-strips/ (2023-05-11)

- https://besenledlight.com/connect-led-strips/